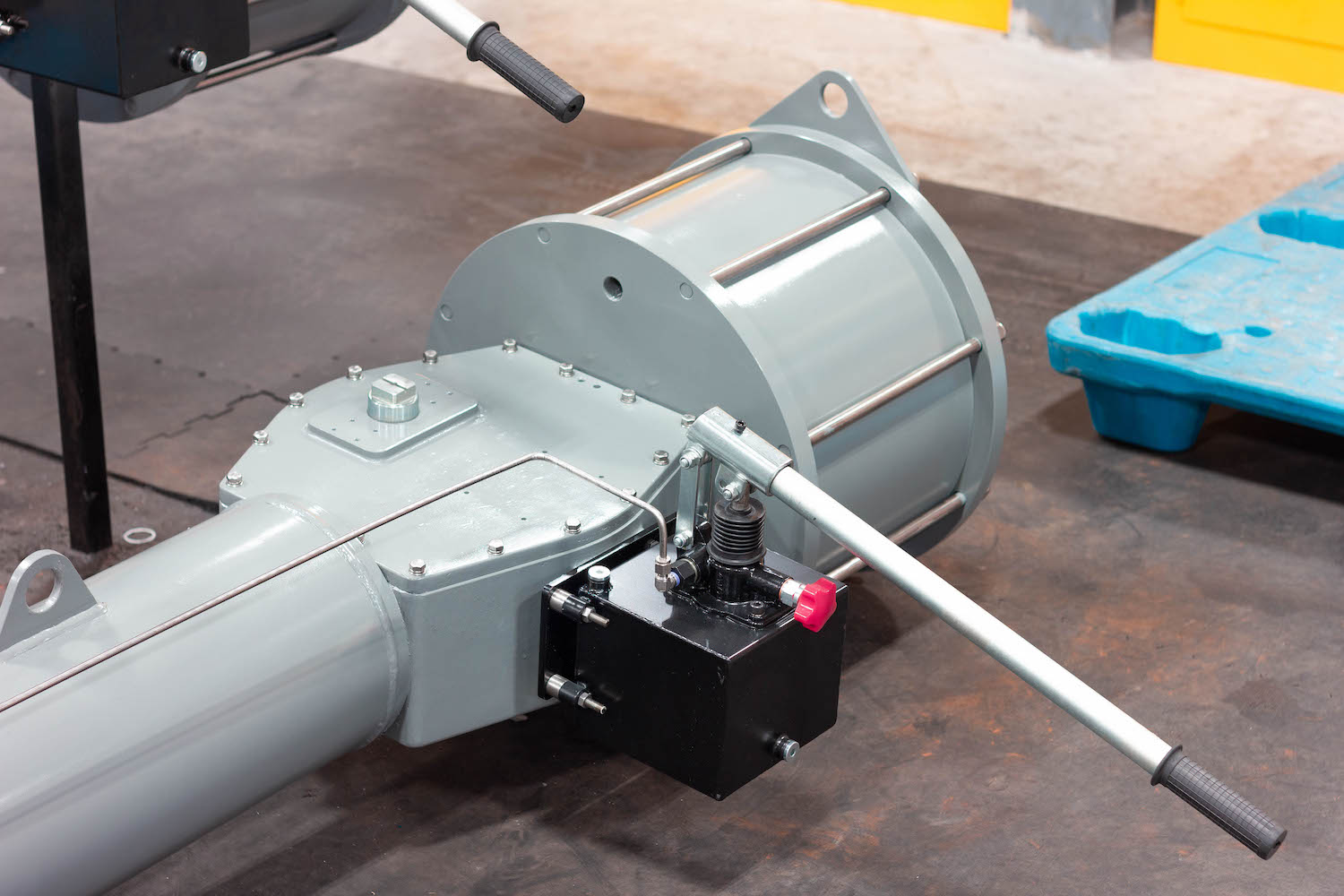

In real life scenarios with critical service valves, there are situations such as the loss of air or loss of power where a valve must be forced into a position other than its current position. In those critical times, the right accessories on an actuator will allow an operator to move a valve from closed to open or open to closed, regardless of the position it was designed to “fail” to. Max Air’s HD line of scotch yoke actuators offers this capability. Shown here is our hydraulic manual override system. A self-contained hydraulic reservoir and hand pump are utilized to power an auxiliary hydraulic cylinder and drive the actuator to the required position. The Double Acting actuator will stroke the valve, manually, either clockwise or counter clockwise as required. The Spring Return unit compresses the spring and drives the actuator to the opposite of it’s fail position. i.e. Opens a valve with a fail closed actuator or closes a valve with a fail open configuration.

Utilizing one of these systems brings a higher level of safety to the automated valve package without interfering with normal operational characteristics.

Case Studies

Scotch Yoke w/ Hydraulic Manual Override System

For Immediate Service in Europe | Call: +39.039.902.0000 or Email: sales@emmetech.com

For Immediate Service in North America | Call: +1.888.842.9998 or Email: sales@maxairtech.com

Distributor List

© 2024 Max-Air Technology.

All rights reserved.

General Terms & Conditions of Sale | Quality Policy | Privacy & Cookies Policy