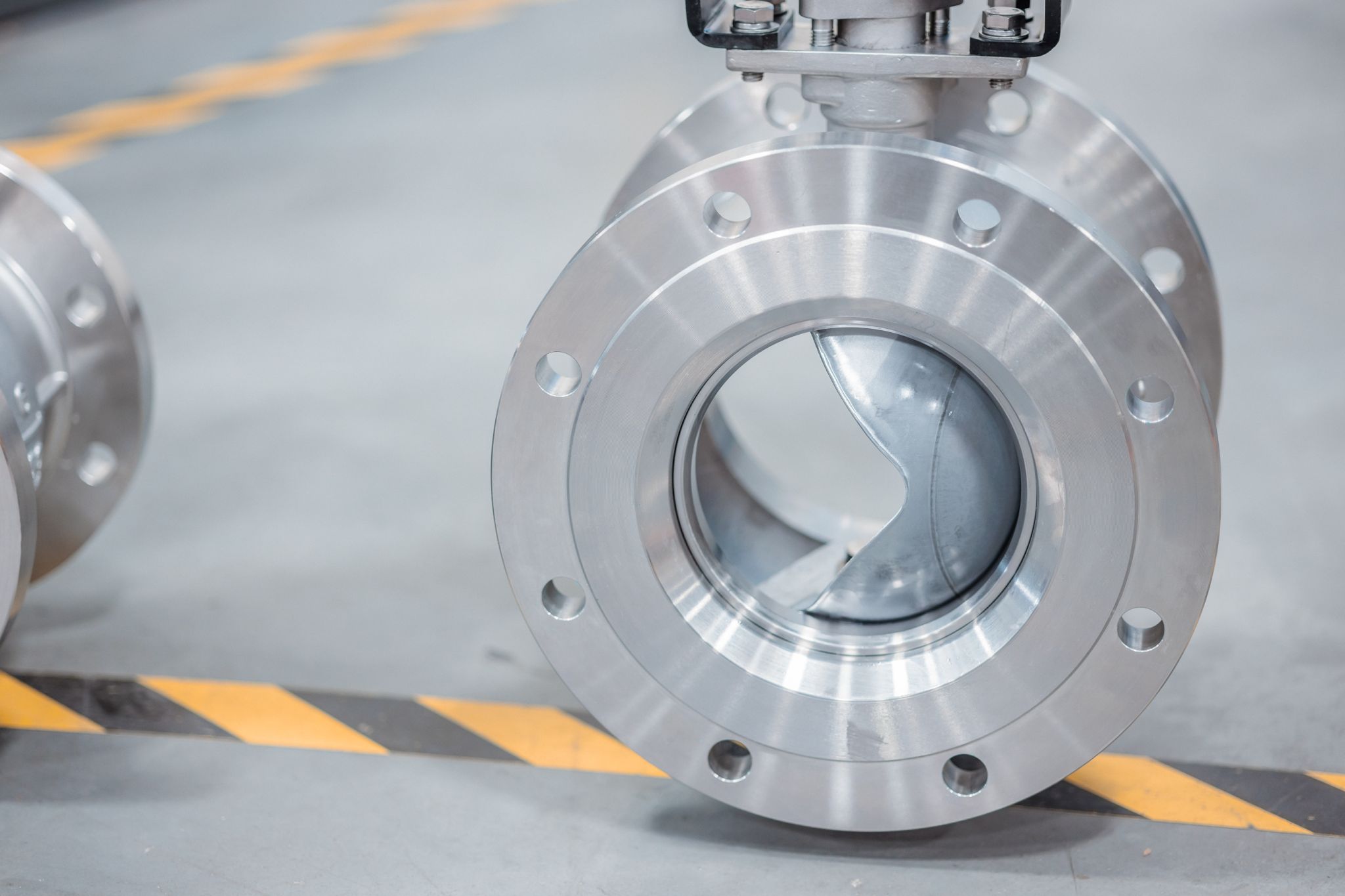

Flow simulation of our Delta T

Cavitation Control Butterfly Valve.

What is Cv and how does it relate to valves?

Valves play a critical role in the regulation of fluid flow. Whether for industrial applications, plumbing, or other processes, selecting the right valve characteristics is essential for achieving efficient and reliable operation. One of the key characteristics of a valve’s performance is the Valve Flow Coefficient, commonly referred to as Cv (or Kv in the metric world). In this article, we will explore what Cv is, its significance, and how it affects the overall flow in a pipeline.

What is Valve Flow Coefficient (Cv)?

Valve Flow Coefficient, or Cv, is a numerical value that quantifies the flow capacity of a valve. It represents the rate at which a specific fluid can pass through the valve when subjected to a pressure drop of 1 psi (pound per square inch). The higher the Cv value, the greater the flow capacity and thus the flow rate through the valve under the associated conditions. Cv is expressed in gallons per minute (GPM) in the imperial system and in liters per minute (LPM) in the metric system.

Mathematically, the relationship between Cv, flow rate (Q), and pressure drop (ΔP) can be expressed as:

Q = Cv * √ΔP

Where:

Q = Flow rate in GPM (or LPM)

Cv = Valve Flow Coefficient

ΔP = Pressure drop across the valve in psi (or bar)

V-Balls can be used to

adjust and/or reduce flow.

What factors influence Cv?

- Valve Size and Shape: The physical dimensions and shape of the valve significantly impact its flow capacity. Larger valves with more open pathways tend to have higher Cv values, allowing for greater flow rates.

- Valve Type: Different types of valves, such as globe valves, ball valves, butterfly valves, and plug valves, have distinct Cv values due to their unique designs and flow characteristics.

- Material and Trim: The material used to construct the valve and its internal components (trim) can affect the Cv value. Smoother surfaces and an optimized trim can improve flow efficiency.

- Pressure Rating: The pressure rating of a valve can determine its ability to withstand pressure differentials, which can influence the Cv value.

- Temperature: The temperature of the fluid passing through the valve affects its viscosity, which, in turn, impacts the Cv value.

- Flow Profile: The flow profile of the fluid, whether laminar or turbulent, also plays a role in determining the Cv value.

Our Segmented V Sesto Ball Valves,

with the proper actuation, provide a

unique modulating control of flow.

Why is Cv important in valve selection?

Choosing a valve with an inadequate Cv can lead to flow restrictions, pressure drops, and potential system inefficiencies. On the other hand, selecting a valve with an excessively high Cv may result in unstable flow conditions, leading to valve damage and increased energy consumption. The appropriate Cv value should be determined based on the desired flow rate, pressure drop, and the characteristics of the fluid and the system.

Cv in pipeline and system design:

In pipeline and system design, Cv values are used to calculate the pressure drop across a valve and estimate the flow rate through the system. Engineers use Cv data to optimize the performance of fluid systems and ensure that valves are appropriately sized. Manufacturers will often provide these valve Cvs for engineers to reference during the design process.

Conclusion:

Valve Flow Coefficient (Cv) is a critical factor in understanding the performance of valves and their impact on fluid systems. Properly selecting valves with suitable Cv values will provide efficient and reliable flow control while avoiding unnecessary pressure drops and energy wastage. Fluid system designers must consider the Cv value along with other relevant parameters to optimize the operation and longevity of pipelines.

Max-Air Technology is here to support your flow control needs. We utilize advanced fluid simulation software to help you identify the right valve for your application. Each solution will come with a detailed report, giving you confidence in your informed decision.