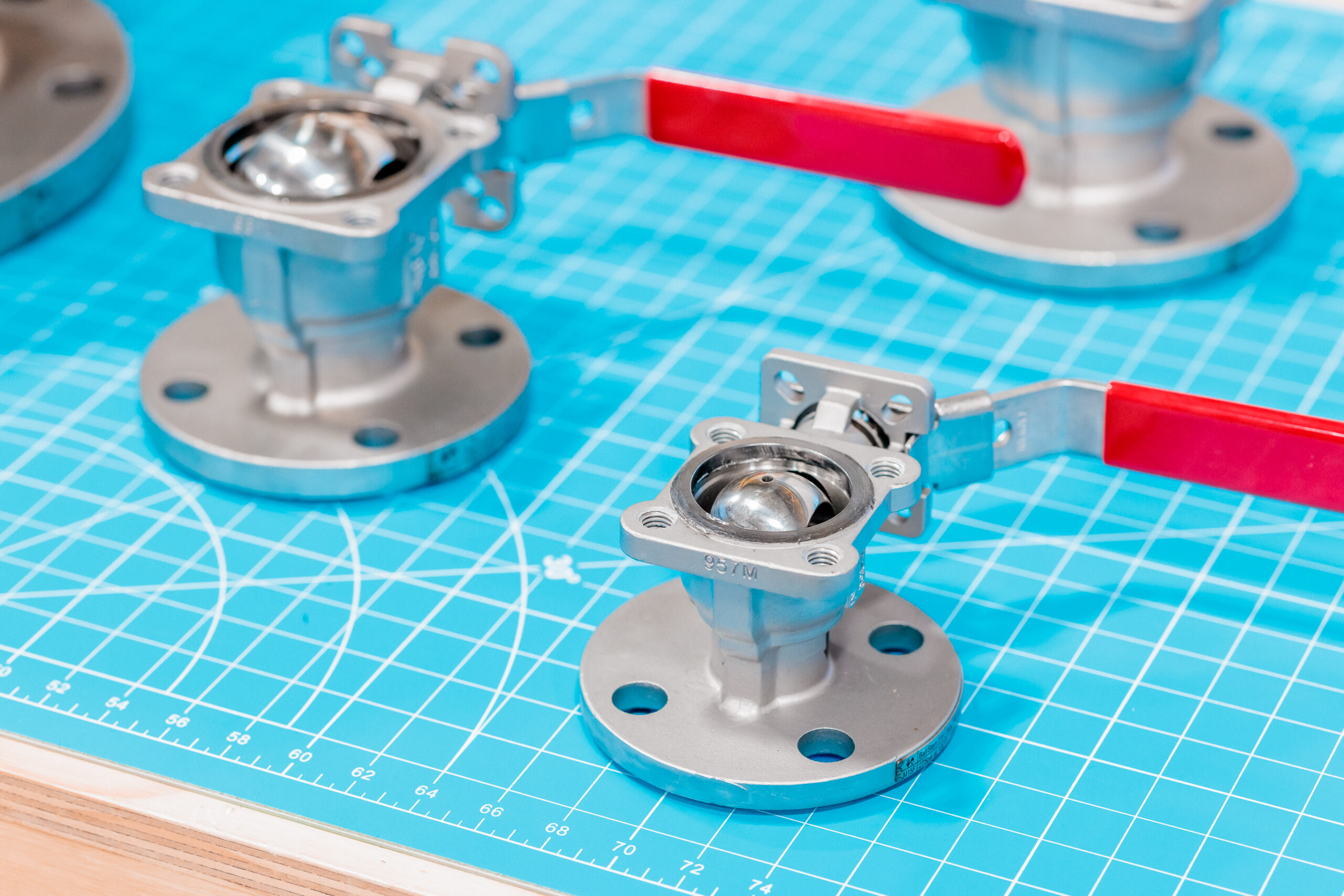

Why Use a Vented Ball?

Ball valves equipped with a “vented ball” generally fall into two functional categories – internally vented or externally vented. It is important to identify which type is needed for your application because there are significant differences between the two functions.

The most common type of vented ball is internally vented and is designed to relieve a buildup of cavity pressure to either the upstream or downstream side of the valve within the pipeline. Importantly, the process media remains contained within the pipeline but is allowed to vent around the valve seat or seal to either upstream or downstream. Allowing the valve to equalize cavity pressure reduces breakaway torque and prevents damage or potential catastrophic failure from over pressurization. Vented balls are used extensively in cryogenic valve LNG applications, where large temperature differences can quickly pressurize the cavity and cause failure if not vented properly.

The other type of vented ball is externally vented and is designed to externally drain or vent pressure from one side of the pipeline while maintaining a positive seal on the opposing side. In this case, process media is ejected from the pipeline directly to atmosphere. For this reason, externally vented ball valves are generally not recommended for liquid service and should never be used in hazardous processes. Externally vented ball valves are commonly used for air supply lines to vent pressure and allow for maintenance in a section of the plant.